We are entering a new chapter of artificial intelligence—one where AI doesn't just live in the cloud, write emails, or predict user behavior. It’s now entering the physical world, interacting with machines, environments, and people in real-time. This evolution, termed Physical AI, is poised to redefine enterprise operations, accelerate automation, and reshape the global workforce.

This article covers the following aspects: introduction to Physical AI, its definition, key components, real-world applications, enterprise implications, comparison with other AI modalities, Large World Models (LWMs), impact on the workforce, roadmap, key adoption challenges, and integration strategies.

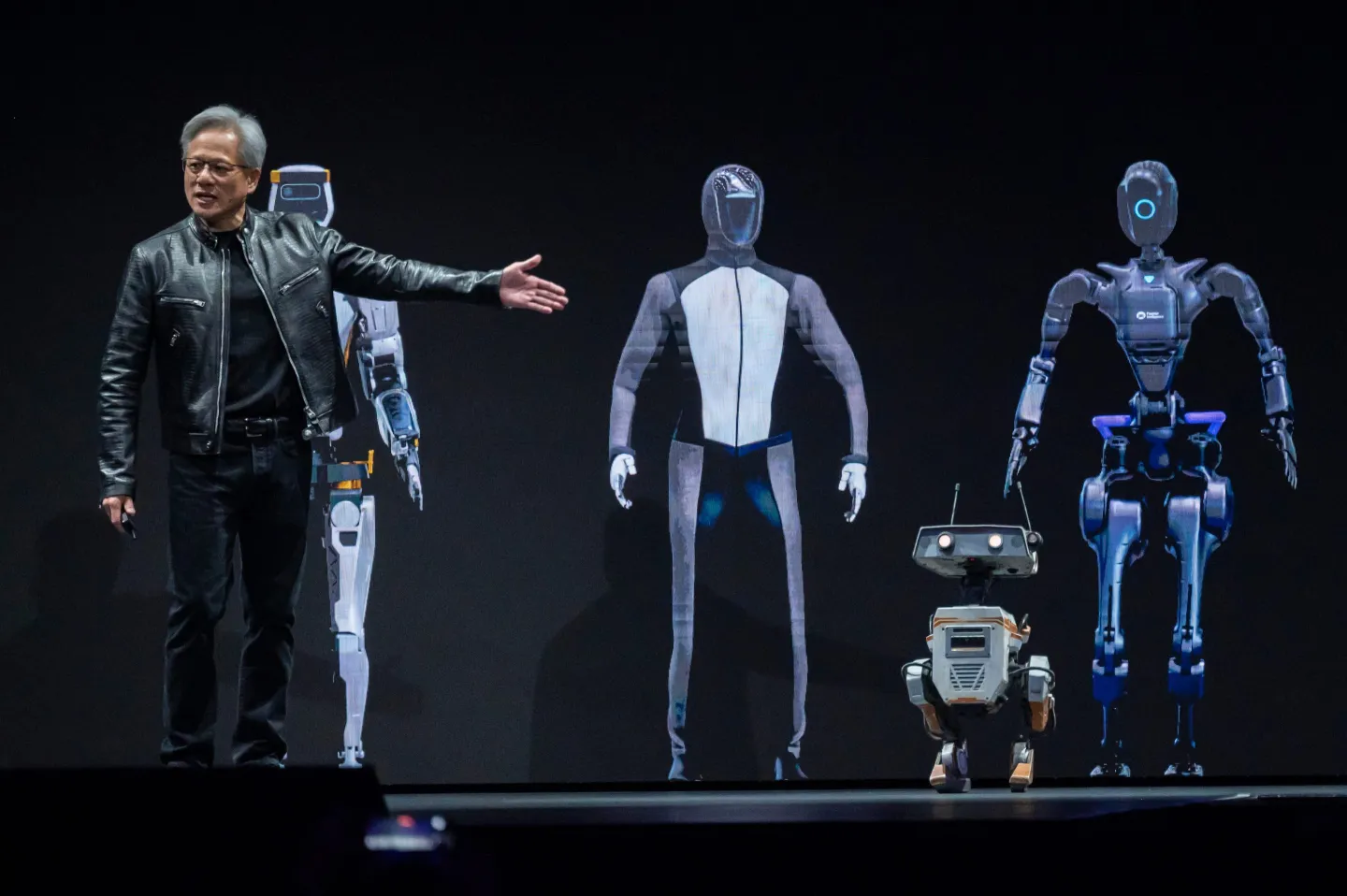

Leaders from the world’s most influential companies are calling attention to this shift. Jensen Huang, CEO of NVIDIA, states, “Physical AI… AI that understands the laws of physics… is the next wave.” Similarly, Julie Sweet, CEO of Accenture, emphasizes, “Physical AI is the next big thing. Write that down.” This transition is not merely speculative; as AI begins to sense, interpret, and act in the physical world, it marks a profound shift in how technology supports businesses.

Physical AI refers to AI systems embedded in machines that directly interact with the physical world through sensors, cameras, actuators, robotics, and other hardware. These systems move beyond screen-based applications, engaging directly with the real world. Consider a robot autonomously moving packages, a self-driving truck predicting road hazards using weather and sensor data, or an AI-driven factory line adjusting operations in real-time for safety and efficiency. Physical AI sees, feels, and responds, bridging the digital and physical divide.

- Sensors & Perception: Gathers physical-world input via cameras, LiDAR, thermal imaging, pressure sensors, etc.

- Reasoning & Interpretation: Uses AI to make decisions in uncertain, dynamic conditions (e.g., a warehouse floor).

- Action & Feedback: Interacts with physical environments through motors, actuators, robotic limbs, etc.

- Learning in the Real World: Constant feedback loop to improve performance in non-simulated, messy environments.

Unlike digital-only AI models, Physical AI operates in dynamic, uncertain, and multi-dimensional environments, necessitating operation amidst noise, ambiguity, and unpredictability.

Physical AI is already impacting several domains:

1. Autonomous Vehicles: Self-driving cars use cameras, radar, and AI to navigate cities, avoid accidents, and optimize routes in real time.

2. Industrial Automation: Robots in factories handle sorting, welding, packaging, and quality inspection with increasing autonomy.

3. Logistics and Warehousing: Autonomous mobile robots (AMRs) navigate facilities, reducing manual labor and improving accuracy.

4. Smart Infrastructure: Physical AI aids cities in managing traffic flow, lighting, waste management, and emergency response using real-time sensor data.

5. Healthcare and Surgery: Robotic-assisted surgeries and intelligent diagnostic devices operate with AI-guided precision.

1. Körber – Warehouse Automation

- Industry: E-Commerce / Logistics

- Impact:

- Deployment: Körber's Operator Eye is an AI-based add-on module that can be integrated with the K.Handle Layer Picker and other machinery. It automatically tracks error patterns, significantly minimizing downtime and human intervention

- Efficiency: Reduction of repetitive errors by up to 75%

- Business Outcome: Reduced downtime, increased throughout

- Source: Körber’s Operator Eye - Körber Supply Chain

2. John Deere – AI in Autonomous Tractors

- Industry: Agriculture

- Impact:

- Autonomy: Self-driving tractors with AI-powered computer vision and sensors analyze crops, optimize routes, and detect pests or anomalies.

- Resource Efficiency: Reduced need for manual labor, and optimized use of water, fertilizer, and fuel.

- Business Outcome: Helped farmers improve crop yields while reducing operational costs. Repositioned John Deere as a technology-driven company.

- Source: Autonomous Tractor | John Deere

3. Ocado – AI-Powered Grocery Fulfillment Robots

- Industry: Grocery / Retail Tech (UK)

- Impact:

- Robotic Grid Systems: Uses hundreds of AI-controlled bots that move across a 3D grid to pick and pack grocery orders.

- Speed & Accuracy: Orders that used to take hours can now be fulfilled in minutes.

- Business Outcome: Their tech arm, Ocado Technology, now licenses its robotic platform to other retailers (e.g., Kroger in the U.S.), transforming into a tech provider

- Source: Grocery Warehouse Automation | Ocado Group

4. Boston Dynamics’ Spot – Industrial Site Monitoring

- Industry: Energy, Construction, Utilities

- Impact:

- Deployment: Spot, the quadruped robot, is used in facilities for monitoring, data collection, and hazardous inspection tasks.

- Safety & Uptime: Reduced the need for humans in dangerous areas (e.g., oil rigs or construction zones).

- Business Outcome: Improved compliance, real-time operational awareness, and reduced insurance claims due to fewer safety incidents.

- Source: Spot | Boston Dynamics

The next evolution involves overseeing entire ecosystems, including smart cities coordinating traffic, public safety, and air quality (e.g., Singapore,

Physical AI offers several key advantages for enterprises. It can cut waste and overhead by detecting inefficiencies and reducing energy, time, and labor waste across physical operations. As demographics shift and labor markets tighten, it can augment a leaner workforce, increasing productivity. Moreover, similar to electricity and the internet, AI will become foundational infrastructure, necessitating that enterprises design for AI-first environments.

| AI Type | Focus |

|---|---|

| Digital AI | Works in virtual environments (chatbots, ads, language models). |

| Agentic AI | Autonomous decision-makers that manage tasks and workflows. |

| Physical AI | Embodied AI systems operating in the real world via hardware. |

| LLMs (Large Language Models) | Excel at text-based reasoning and prediction. |

| LWMs (Large World Models) | Trained to understand and act in 3D physical space using multi-modal data. |

Large World Models (LWMs) are to the physical world what LLMs are to language. Trained on visual, spatial, and sensor-rich data, LWMs empower AI agents to interpret physical surroundings, make context-aware decisions, and execute physical actions. They are the engines behind warehouse automation, real-world navigation, and human-machine collaboration.

The expansion of Physical AI will transform the nature of jobs, automating routine physical tasks and creating new roles around AI maintenance, oversight, and human-machine collaboration. Entire industries will redesign workflows around AI-enhanced operations. The question is not if this will happen but how fast, and how ready we are.

Companies must start planning for the rise of Physical AI now by investing in infrastructure (sensors, robotics, real-time data systems), upskilling teams in AI, robotics, and automation ethics, and reimagining workflows with AI as a co-pilot rather than a replacement.

Companies must start planning for the rise of Physical AI now by investing in infrastructure (sensors, robotics, real-time data systems), upskilling teams in AI, robotics, and automation ethics, and reimagining workflows with AI as a co-pilot rather than a replacement.

Organizations should start planning early—before full Agentic AI maturity—but deploy incrementally. While mastering Agentic AI before exploring physical AI is not strictly necessary, successful deployment of physical AI typically requires a foundation of digital AI maturity. The stages often unfold as follows:

- Foundational AI Maturity, including digital automation, AI model governance, and basic process digitization with sensorized or digitally monitored physical environments. If these basics aren’t in place, physical AI won't have the “eyes and ears” to act meaningfully.

- Intermediate Agentic or Decision-Making AI, exemplified by AI systems making autonomous decisions in workflows. This builds confidence in AI “autonomy” in a virtual context, a precursor to trusting embodied AI with physical actions. Agentic AI isn’t a strict prerequisite; in some industries, physical AI started in parallel with agentic systems.

- Strategic Inflection Point: Plan Physical AI when there are predictable, repeatable physical tasks with measurable ROI potential, digital infrastructure supports real-time data capture and feedback, and leadership buy-in exists for automation and human-robot collaboration.

For instance, Amazon introduced warehouse robots (physical AI) in parallel with software agents managing inventory, and John Deere integrated physical AI (autonomous tractors) before fully developing agentic software layers. Organizations do not need to master Agentic AI first but require digital AI maturity, sensorized environments, clear use cases with ROI, and a staged, test-and-learn mindset. Planning should commence during or just after early digital AI success, viewing Agentic AI and physical AI as parallel tracks.

Transitioning from digital AI to physical AI introduces complexity. Key challenges include:

1. Infrastructure and Environment Readiness: Physical AI requires an instrumented environment (sensors, IoT, real-time connectivity), which many companies lack.

2. System Integration Complexity: Physical AI must interact with multiple legacy systems, and a lack of interoperability can delay deployments.

3. Safety, Risk, and Liability Concerns: Physical AI can cause physical harm if it malfunctions, necessitating rigorous safety testing and compliance.

4. Workforce Disruption and Change Management: Employees may resist working with physical AI, requiring training, clear communication, and redesigned roles.

5. High CapEx and ROI Uncertainty: Physical AI often requires significant capital investment, and ROI can be harder to calculate than SaaS-like digital AI tools.

6. Edge Intelligence and Real-Time Decisioning: Many physical AI applications need low-latency decision-making, necessitating strong edge computing infrastructure.

7. Security and Privacy Risks: Physical AI systems often use surveillance-capable sensors, raising data protection concerns.

8. Unpredictability of the Physical World: The real world is messy and dynamic, requiring robust simulation training and continuous learning loops.

| Category | Key Challenge |

|---|---|

| Technical | Real-time processing, edge AI, system integration |

| Organizational | Workforce disruption, change management |

| Financial | High upfront costs, unclear ROI |

| Legal/Safety | Risk of injury, liability, compliance |

| Operational | Environment prep, unpredictable real-world variables |

Successful integration begins with defining strategic goals, determining how AI can enhance the brand, optimize operations, or boost sales. Organizations should assess existing data systems and infrastructure, investing in upskilling or external expertise to address any gaps. Effective integration requires resource planning, transparent communication about potential risks, and measurable milestones to track progress.

Just as the internet revolutionized communication and LLMs redefined digital knowledge work, Physical AI will transform real-world operations across sectors. We’re bringing AI into the world itself.

.png)